Harley Davidson Exhaust Bolt Torque

Harley-davidson Torque Spec Chart.

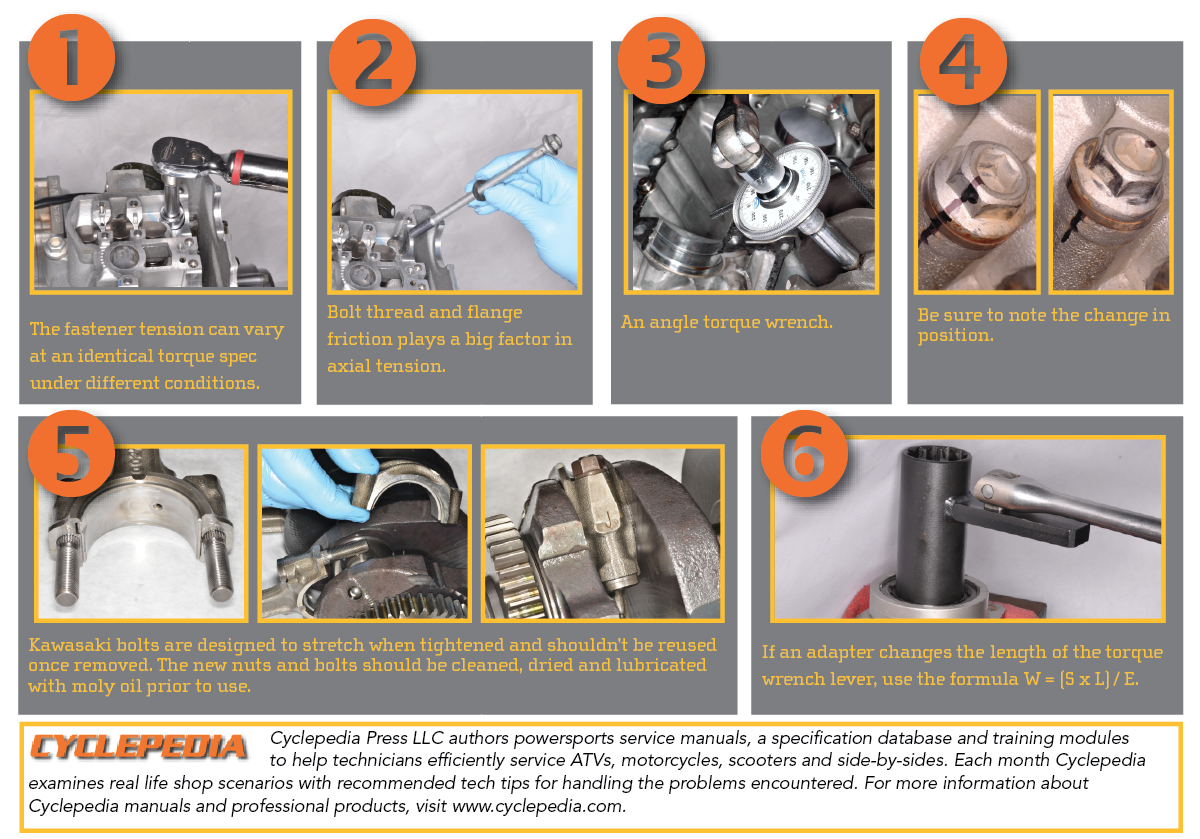

Harley davidson exhaust bolt torque. Tighten each bolt to 7-9 foot pounds of torque. Gaskets are soft and can squish into the port area if tightened too much. Today Doc Harley explains the importance of checking the torque on your exhaust bracket boltsharleydavidson torque motorcycles.

Exhaust Torque specs. Ad Fast Free Shipping on Orders Over 40. 516585 Nm 3843 ft-lbs clamp bolt NOTICE Wipe all fingerprints off of exhaust system components after installation and before starting engine.

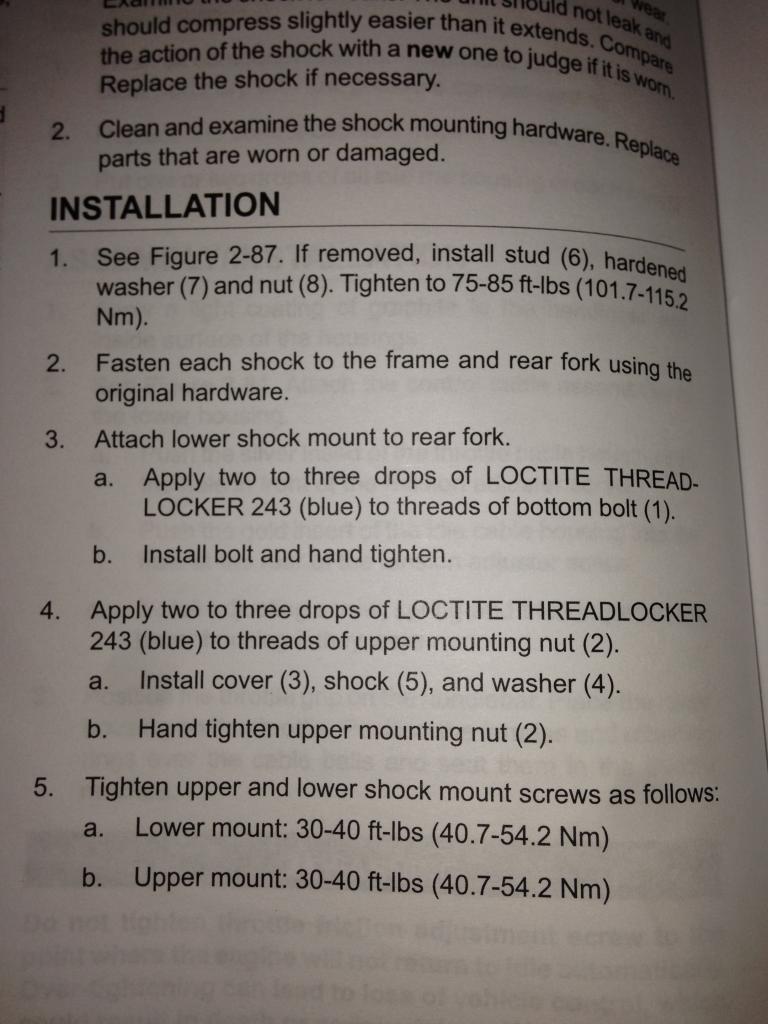

RINEHART exhaust system you should seek the advice andor skill of a professional mechanic. Route the oxygen sensor wiring back to their respective plugs and secure with wire ties as necessary. Insert the Torque Cones.

Harley Davidson Master. Step 6 Raise the exhaust pipes back up and thread the head bolts and rear mounting bolts into position. Expert Gear Advice From Riders.

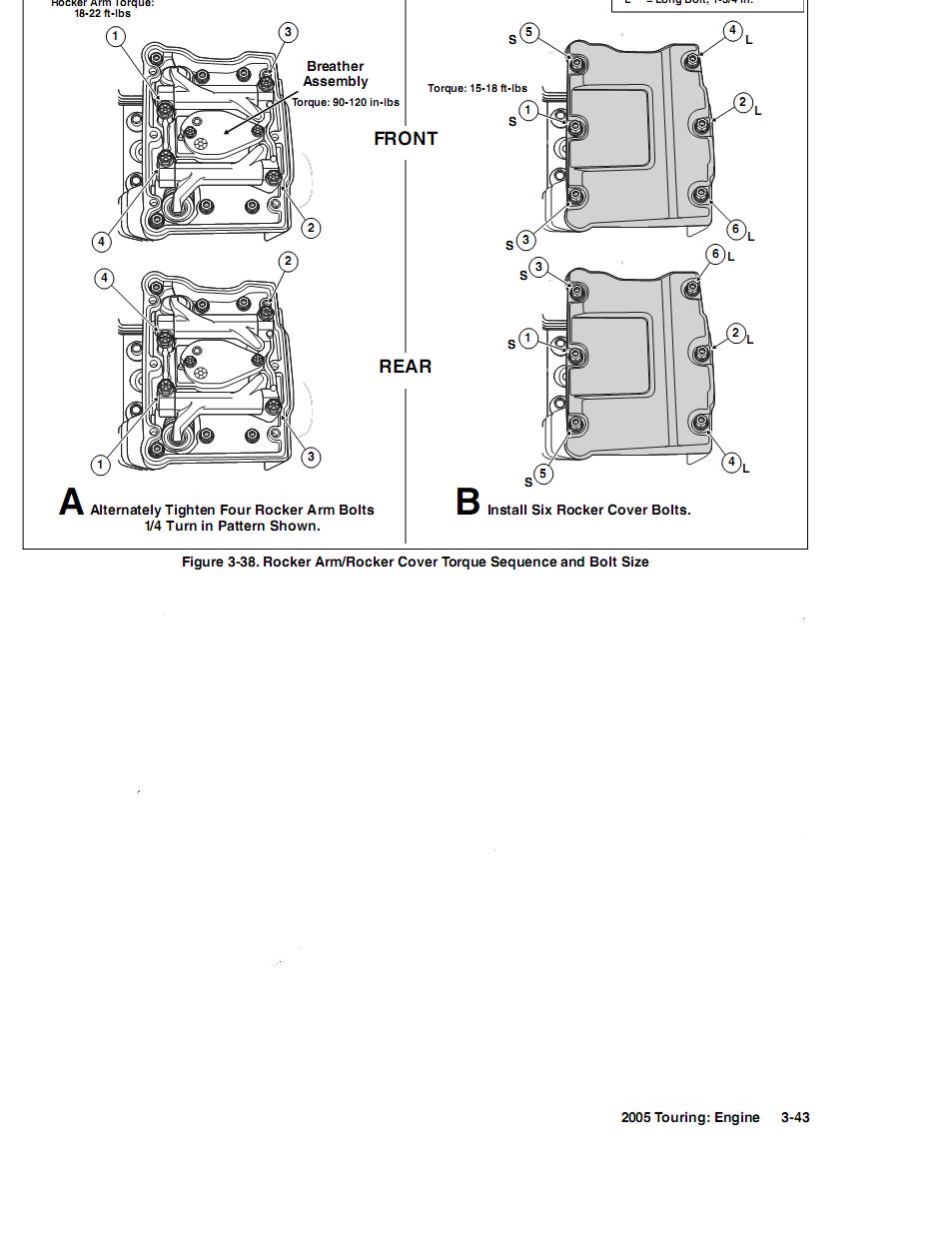

Tighten each bolt to 12-15 foot pounds of torque. Torque the cylinder stud nuts to 60 to 80 inch-pounds using a torque wrench. Repeat on the rear cylinder.

I just use lock washers on my ex. Tighten the top nut of the front cylinder head exhaust flange to 9-18 in-lbs 1-2 Nm then tighten the bottom nut to 100-120 in-lbs 113-136 Nm final tighten the top nut to 100-120 in-lbs 113-136Nm then tighten the bottom nut of the rear cylinder head exhaust flange to 9-18. Ad Fast Free Shipping on Orders Over 40.